JINTEN Technology focuses on the solution of heat dissipation interface, H2 is better than H1

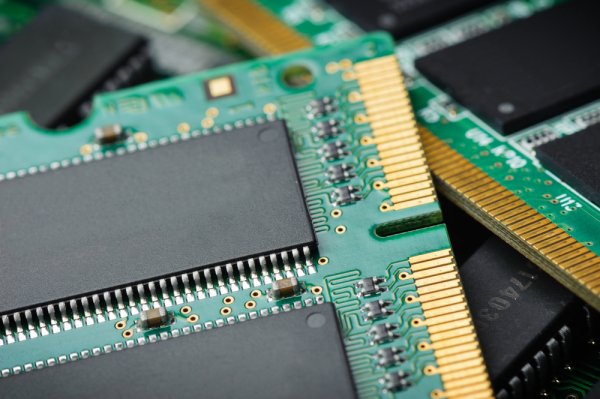

Semiconductor advanced packaging equipment factory Jaten Technology held a pre-employment presentation meeting. Jaten Technology stated that under the successful entry of key hot interface process technology into the AI, GPU and high-performance computing (HPC) chip advanced packaging market, the company received NT$1.145 billion in 2024, an annual increase of NT$293 billion, an annual increase of 83.04%, and an annual increase of NT$12.02 billion in 2024. 80.75%, excellent performance. In the first half of 2025, the revenue also reached 805 million yuan, an annual increase of 43.38%, setting a new year-on-year high.

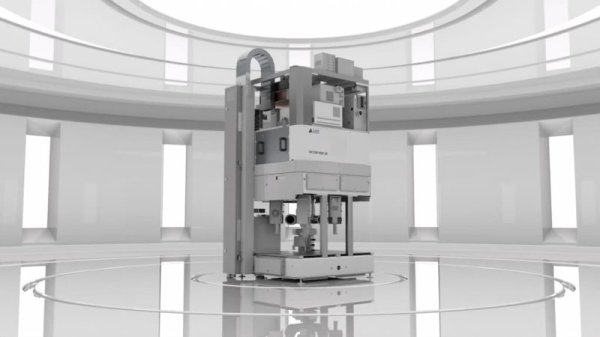

Yen Teng Technology pointed out that the company has been deeply engaged in the semiconductor packaging industry for more than 30 years. The products have focused on point-of-stainless steel sheet pressure combiner and automatic optical detection (AOI) equipment, and are used in the key process of advanced packaging, helping customers to effectively improve packaging yield and production efficiency. Among them, the glue-filled sheet pressure equipment is used in the heat pressure process of wafers, heat interface materials and uniform heat sheets to solve the heat dissipation bottles faced by high-power wafers such as GPUs and AI wafers.

In addition, Jaten Technology has further developed the best thermal interface material steel sheet (Metal TIM) processing equipment, providing automatic equipment including high-efficiency thermal interface materials, heat dissipation sheet (all-heat sheet), frame spot glue, heat pressure and AOI full-process, meeting the extreme requirements of applications such as AI and HPC for heat dissipation performance. Compared with international equipment manufacturers, Essent Technology has the advantages of local and real-time customized service, which can quickly respond to customer diverse product production needs, reduce production costs and improve production efficiency. At present, it has successfully entered the top seven supplier chains of world capsized testers, including Telco, Sun and Moonlight, Silicon Products, Licheng, Chang Electric, Huatian and Tongfu Microelectronics, etc., which are all their long-term customers.

In terms of the construction structure, Janet Technology focuses on high-additional value equipment and services, including point-of-size plate pressure equipment, AOI visual inspection system, and fixture products required to package chips, which keeps the overall gross profit margin at an excellent level and further strengthens the company's profitability quality, especially as the rapid growth of global AI applications, leading to the surge in demand for advanced packaging. The glue-film pressure and AI testing equipment technology provided by Jaten Technology is very high, with few competitors, and has high access barriers, becoming the core energy for stable investment and profits.

At present, Wang Teng Technology has introduced equipment mainly for advanced packaging, and has continued to benefit from market demand and responded to hot orders. It has successfully exceeded NT$150 million since May 2025, and it is also planned to expand the market to meet the market. In terms of research and development, we will continue to invest in the development of spraying technologies such as AOI and Metal TIM, Liquid Metal, and phase change materials. Wang Teng Technology said that the overall system can see the outlook and is expected to be better in the second half of 2025 than in the first half of 2026, and the overall industry will be more fun in 2025.